The increasing attention that organizations and institutions around the world are dedicating to the environment has led, in recent years, to various industrial sectors and to put on the market new and “green” products, capable of providing users with solutions that are at the same time ecological, functional and that follow the new market trends. This is the case of packaging manufacturing companies, which alongside a wide range of plastic products, are using a large part of their resources to design and offer buyers high-performance products aimed at establishing a virtuous circular economy, which is good for both to the environment and to the wallet.

The most innovative solution in the world of packaging

This is the case of cushionPaper™, an ecological packaging of great interest because it is a real substitute for plastic materials and a harbinger of savings on several levels.

By exploiting the technical characteristics of corrugated cardboard, in fact, cushionPaper ™ is not only able to be the best ally for those who need to pack products to be shipped, but also for those looking for an ecological and economic solution to their distribution needs. But what is it exactly? What advantages does it bring? And how can you use it?

What is cushionPaper™

These are paper-based packaging bubbles that are the best alternative to plastics such as polystyrene, film, air cushions for vacuum filling and polyurethane foam.

It is in fact made through a production system that creates waves from 10 to 20 mm high and generates 50% more corrugation than traditional corrugated cardboard, thus making it a product that can best satisfy any packaging requirement.

The high resistance to vertical compression of its waves, for example, allows cushionPaper ™ to be rolled to fill the empty spaces between the product and the container and to lock heavier products in the boxes, while its flexibility makes it suitable for wrapping in protective function even the smallest and most fragile objects.

Come si usa cushionPaper™

Present on the market both in sheets and in reels, cushionPaper™ can be easily positioned at the packaging station and is ready for use: the packing operator, in fact, does not require any special training for its use.

At the same time, however, it is good to know the different types that characterize this product: its various technical examinations, in fact, you can choose between three different models; knowing them all means being clear which of them to apply to the right objects to be packaged in order to preserve them at best at the time of shipment.

cushionPaper™ Light

Its thickness, with high waves between 15 and 20 mm, and its 19 mm “wave”, allows you to secure the most fragile or irregularly shaped objects.

cushionPaper™ Strong

All the strength of a resistant packaging enclosed in a thickness between 10 and 15 mm and a wave of 12 and 19 mm: with this product, the heaviest and most voluminous products can be secured.

cushionPaper™ Wrap

Equipped with a thickness and a wave of 12 mm, its hyper-resistant and roll-up formula effectively protects all types of products (small, fragile, heavy or bulky), from the shocks and vibrations that occur during transport .

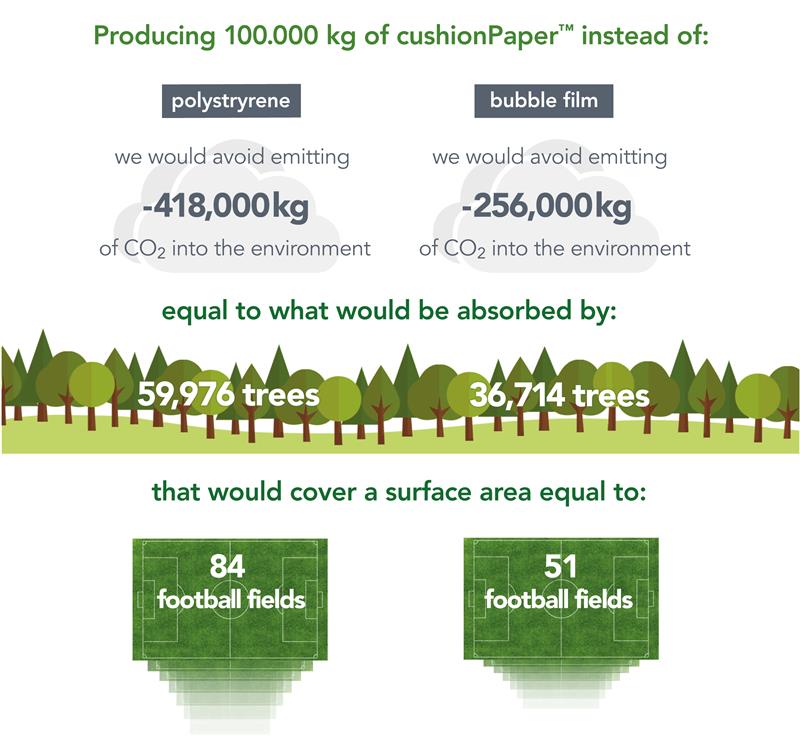

A 100% ecological (and economical)

In recycled and recyclable paper and created from an FSC® certified raw material, cushionPaper™ is a solution perfectly in line with the most recent market trends.

According to Conai’s 2019 Sustainability Report (National Packaging Consortium), in fact, packaging is increasingly oriented towards using raw materials deriving from renewable and compostable fibers, as a strategic element for the management of cellulosic waste in synergy with organic waste.

It is no coincidence that the greatest contribution to the circularity of the Italian paper sector derives precisely from the comparison of packaging: at national level, waste used in production processes was equal to 5 million tons in 2017 and over 92% of use ( 4.6 million) is in the packaging sector.

This attention leads to real savings also in economic terms: the reduction of disposal costs, added to the elimination of items such as equipment, molds and dedicated design, make cushionPaper™ a product capable of exceptional performance at an extremely advantageous price.