Elimination of waste, reduction of energy consumption, but also supply of renewable sources and recourse to reuse and recycling. There are many actions available to man able to lead to the realization of that type of “green” economy (and which today aspires to become “blue”) capable of leading to a halt in the production of waste, the emission of CO2 and the achievement of a situation of environmental sustainability that benefits not only health but also the national and global economy.

The production, use and disposal of plastic in numbers

But how far is there still to go before real change occurs? According to the numbers, a lot. According to a recent WWF research, in the Mediterranean Sea there are 570 thousand tons of plastic that end up in the water every year, the equivalent of 33 thousand bottles per minute. Italy, then, is the largest producer of plastic products in the Mediterranean area and the second largest producer of waste: it generates almost 4 MT of waste a year.

To this is added, on a global level, the issue of disposal: according to a recent study by Tearfund, the incineration of plastic, if done by inadequate structures for the recovery and recycling of the material, would cause the production of 4.6 million tons of carbon dioxide and other greenhouse gases, equal to the emissions of 2 million cars.

The world of ecological packaging

However, these uneasy data should not make us think that all is lost. The packaging industry is in fact increasingly fielding products and solutions that can take into account two fundamental objectives: to create functional packaging and, at the same time, respectful of the environment because it is ecological.

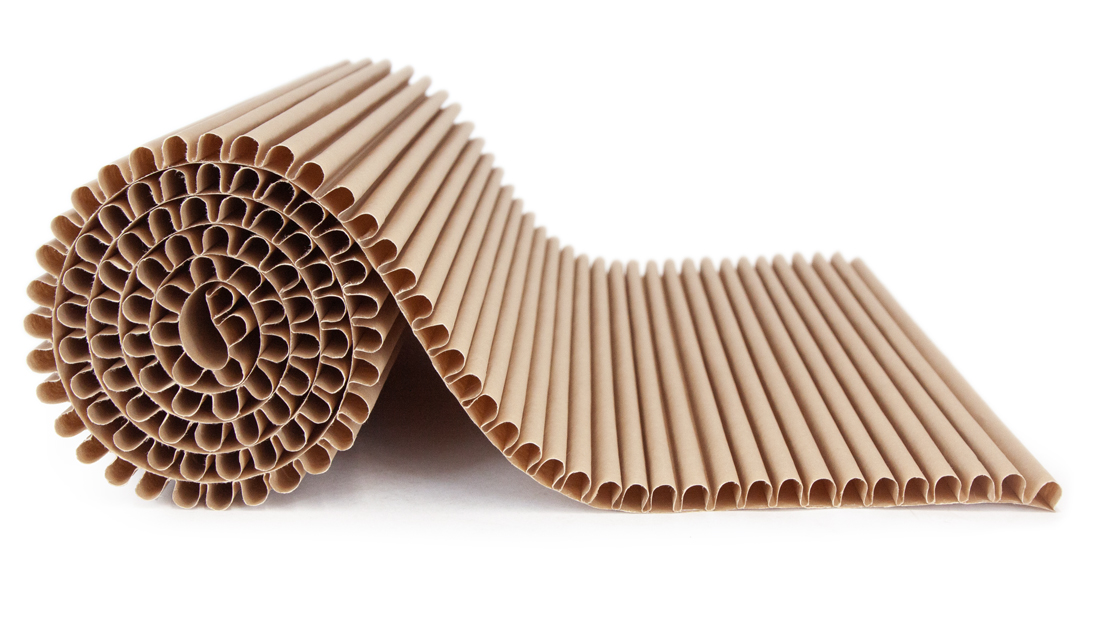

This is the case of an innovative product and fully attributable to the ecological packaging on the market today: we are talking about cushionPaper™, which is the best substitute for plastic (bubble film, polystyrene and polyurethane) to wrap and protect products. to be sent, as well as to fill in the empty spaces that are created between these and the boxes that contain them.

These performances go hand in hand with full respect for the environment and make cushionPaper™ the best choice among ecological packaging on the market. Among these, in fact, there are many that replace traditional plastic materials (such as bubble film, polystyrene chips, polyurethane foam and air cushions) with products processed or extracted from substances present in nature: just think of the bubble wrap bags of recycled plastic or chips based on corn starch or peas and water or, again, air cushions made up of corn starch or additives that accelerate the decomposition of the material by 50%. However, these materials are expensive and, in some cases, it is not possible to achieve the desired performance.

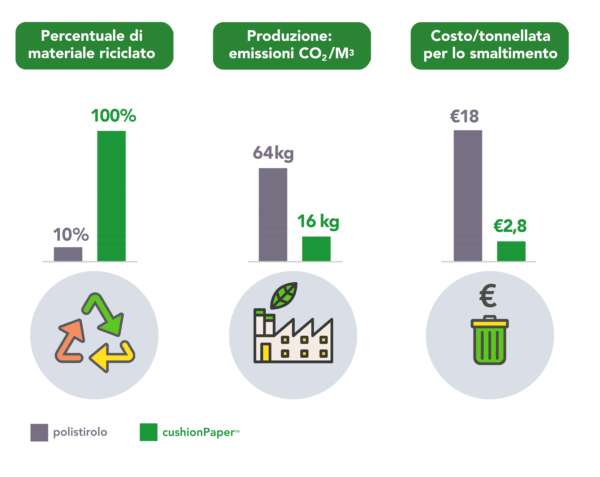

cushionPaper™, one of the cheapest ecological packaging on the market, wins the challenge of eco-compatibility and functionality: an equal volume, in fact, reduces CO2 emissions and problems related to disposal. A few numbers? Compared to polystyrene (EPS), in fact, it is made of 100% recycled and recyclable material, it produces only 16 kg of CO2 per M3 compared to 64 kg of polystyrene (EPS) and has a disposal cost of 2.8 euros per ton compared to 18 euros for polystyrene (EPS).

Not only. In addition to being produced with recycled and recyclable paper, and therefore perfectly inserted in a context of circular economy, the raw material used to produce cushionPaper™ is FSC® certified. This means that anyone who uses the cushionPaper ™ has the guarantee that the product they are using is made of paper (and for other FSC® certified products also wood) deriving from responsibly managed forests.