Thanks to filling packaging it is possible to fill, in different ways, the empty spaces that are created between a product and the internal walls of a box that contains it, usually in view of transport. The fillers, therefore, become necessary elements to preserve the integrity of an object, often when it is fragile and risks being damaged (if not even broken) by internal settlements and external impacts.

Given their importance in an increasingly projected market of boxes and containers for the shipment of objects, such as eCommerce, the companies producing filler packaging have over time expanded the range of these products, ranging from plastic, foam, organic products and paper.

And the latter will be at the center of our discussion in this article: thanks to their technical characteristics, which make them resistant and malleable at the same time, and their ability to be eco-sustainable, paper as well as cardboard can be counted among the best filler packaging on the market.

Paper and cardboard: the technical characteristics

There is no cardboard without paper, and vice versa. The most widely used paper in the world of packaging is the “kraft” type: its name, which in German means “strength”, identifies this material for its high mechanical characteristics and is produced with sulphate coniferous cellulose.

Well, cardboard is nothing more than a paper product with a thickness and weight expressed in grams per square meter greater than those of paper. In fact, cardboard is defined as such only if it has a thickness greater than 5 mm and a weight between 350 and 1000 gr / m2.

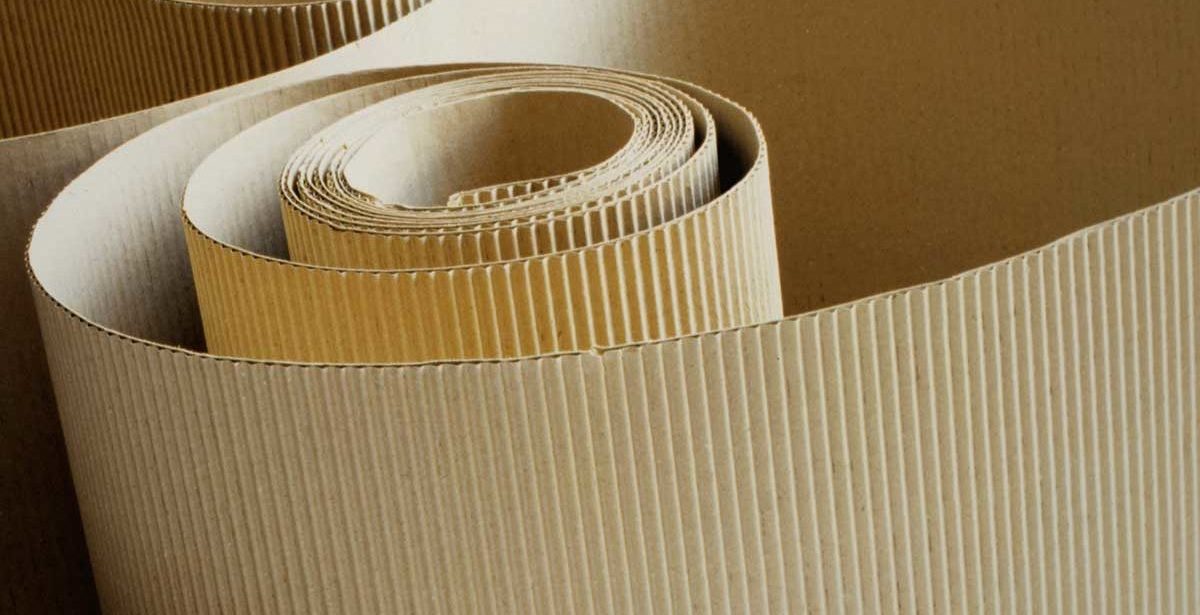

In its wavy version, widely used for packaging, it is composed of two fundamental elements: the cover and the wave. The first is a flat sheet of paper (usually kraft), on the surface of which an adhesive is used to glue the crests of the waves. The latter, on the other hand, are produced with cheaper and more resistant material than kraft paper and are modeled with special metal cylinders on whose surfaces gears-shaped grooves are obtained.

Finally, the height of the waves can vary from 1.5 to 5 mm and, since they can overlap two or more sheets of corrugated cardboard through the interposition of a sheet of flat cardboard called a central stretched sheet, there can be combinations different corrugated cardboard that lead to final thicknesses that reach 15 mm.

Uses for filler packaging

As we have already said, both paper and cardboard perform their role as filler packaging very well. The kraft paper (commercially available in the form of a reel and padding) is crumpled and placed in the gaps between the container and the product.

Alongside it, among the most used, also the tissue (very thin and soft, to be used for wrapping, padding and as an intermediate layer), the crepe (ideal for the protection of tubes, profiles, movable feet and mechanical parts) and straw (havana paper fibers folded like an accordion).

Corrugated cardboard can be used to form blocks or shock absorbing pads and can be shaped to form compartments, thicknesses and divisions inside the container, especially if the objects to be transported are more than one. Furthermore, it can be cut into strips of different sizes to create a so-called “floating” packaging system or it can be assembled in order to create corners and profiles with the purpose not only of filling but also and above all protective.

The latter type, in fact, allows you to fix a product inside its container and, through special grooves, to implement a “suspension” packaging, in order to keep a packaged product away from the walls of the container to protect it.

There is another type of packaging cardboard, called “honeycomb” due to its mold, which can be used as a filler, shock absorber, separator and spacer. It is a product that uses a “technology” present in nature, the alveolar one typical of the hive, in order to produce a layered packaging system that allows you to transport objects in total safety, locking them inside the containers or simply filling empty spaces in order to cushion any internal and external impacts.